- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Flash version

© UniFlip.com

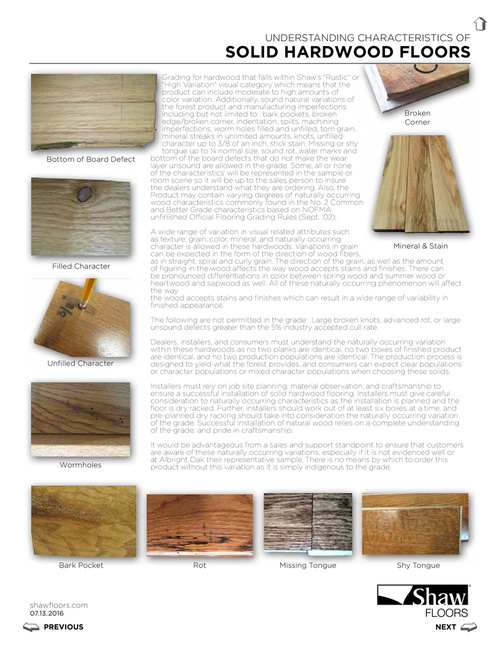

SOLID HARDWOOD FLOORS

Grading for hardwood that falls within Shaw’s "Rustic" or "High Variation" visual category which means that the product can include moderate to high amounts of color variation. Additionally, sound natural variations of the forest product and manufacturing imperfections including but not limited to: bark pockets, broken edge/broken corner, indentation, splits, machining imperfections, worm holes filled and unfilled, torn grain, mineral streaks in unlimited amounts, knots, unfilled character up to 3/8 of an inch, stick stain, Missing or shy tongue up to ¼ normal size, sound rot, water marks and bottom of the board defects that do not make the wear layer unsound are allowed in the grade. Some, all or none of the characteristics’ will be represented in the sample or room scene so it will be up to the sales person to insure the dealers understand what they are ordering. Also, the Product may contain varying degrees of naturally occurring wood characteristics commonly found in the No. 2 Common and Better Grade characteristics based on NOFMA unfinished Official Flooring Grading Rules (Sept. ’02).

UNDERSTANDING CHARACTERISTICS OF

Broken Corner

Bottom of Board Defect

Filled Character

A wide range of variation in visual related attributes such as texture, grain, color, mineral, and naturally occurring Mineral & Stain character is allowed in these hardwoods. Variations in grain can be expected in the form of the direction of wood fibers, as in straight, spiral and curly grain. The direction of the grain, as well as the amount of figuring in the wood affects the way wood accepts stains and finishes. There can be pronounced differentiations in color between spring wood and summer wood or heartwood and sapwood as well. All of these naturally occurring phenomenon will affect the way the wood accepts stains and finishes which can result in a wide range of variability in finished appearance. The following are not permitted in the grade: Large broken knots, advanced rot, or large unsound defects greater than the 5% industry accepted cull rate. Dealers, installers, and consumers must understand the naturally occurring variation within these hardwoods as no two planks are identical, no two boxes of finished product are identical, and no two production populations are identical. The production process is designed to yield what the forest provides, and consumers can expect clear populations or character populations or mixed character populations when choosing these solids. Installers must rely on job site planning, material observation, and craftsmanship to ensure a successful installation of solid hardwood flooring. Installers must give careful consideration to naturally occurring characteristics as the installation is planned and the floor is dry racked. Further, installers should work out of at least six boxes at a time, and pre-planned dry racking should take into consideration the naturally occurring variation of the grade. Successful installation of natural wood relies on a complete understanding of the grade, and pride in craftsmanship. It would be advantageous from a sales and support standpoint to ensure that customers are aware of these naturally occurring variations, especially if it is not evidenced well or at Albright Oak their representative sample. There is no means by which to order this product without this variation as it is simply indigenous to the grade.

Unfilled Character

Wormholes

Bark Pocket

Rot

Missing Tongue

Shy Tongue

shawfloors.com

07.13.2016